| Availability: | |

|---|---|

| Quantity: | |

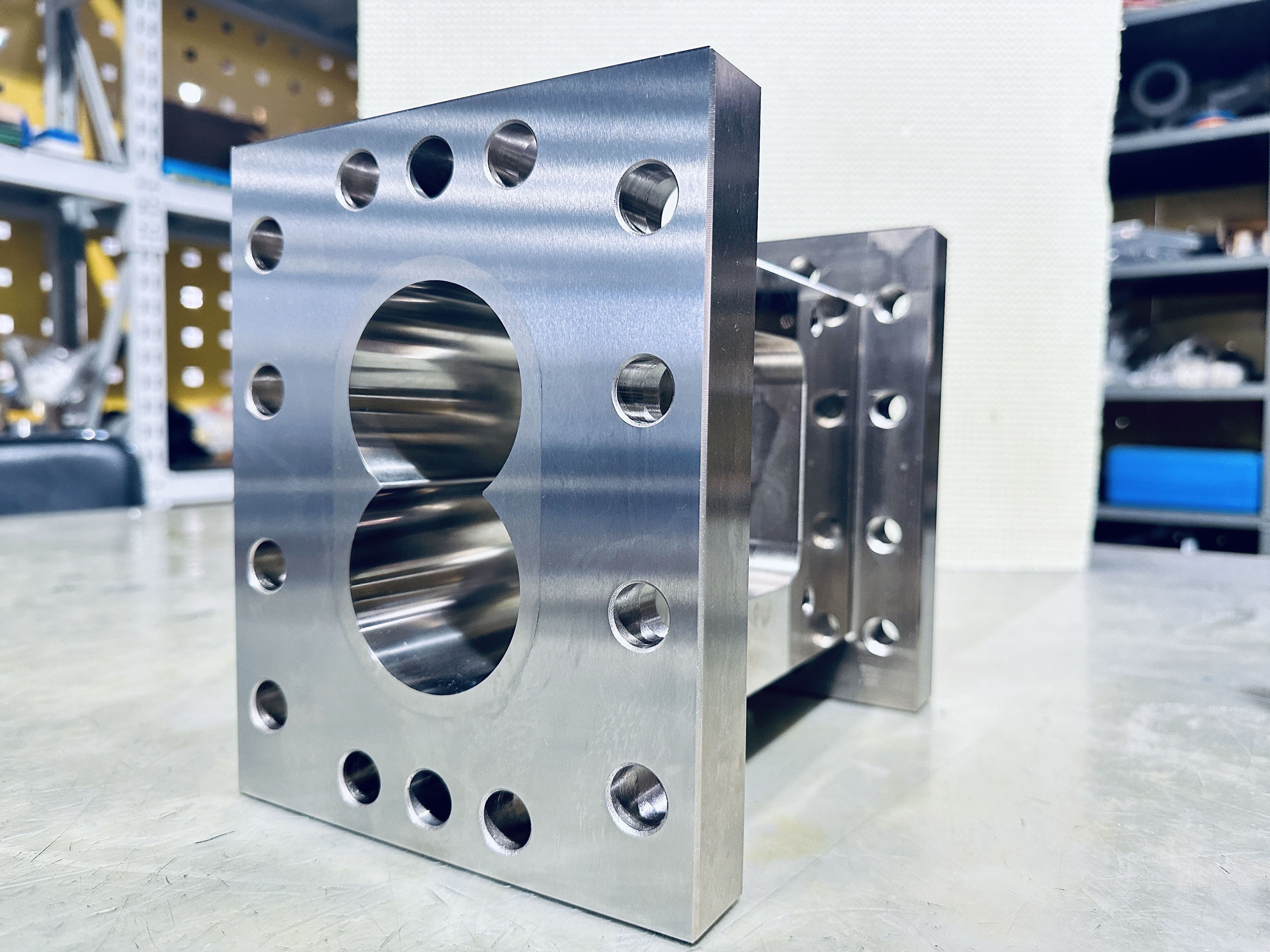

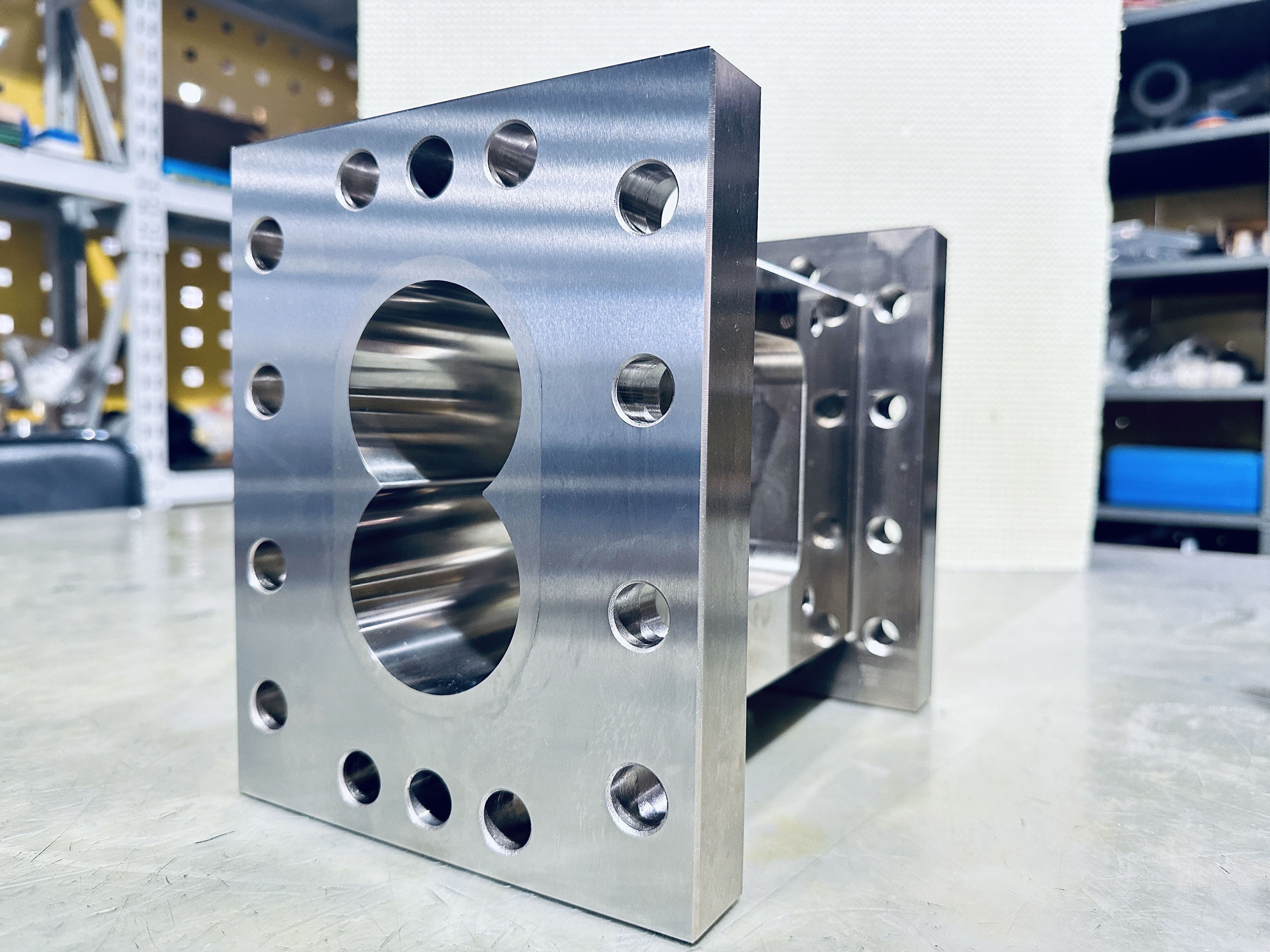

Extruder Side-Feed Barrel

Product Name: Extruder Side-Feed Barrel

Model:φ11 mm ~φ350mm

Applicable Brands:Most well-known extruders on the market

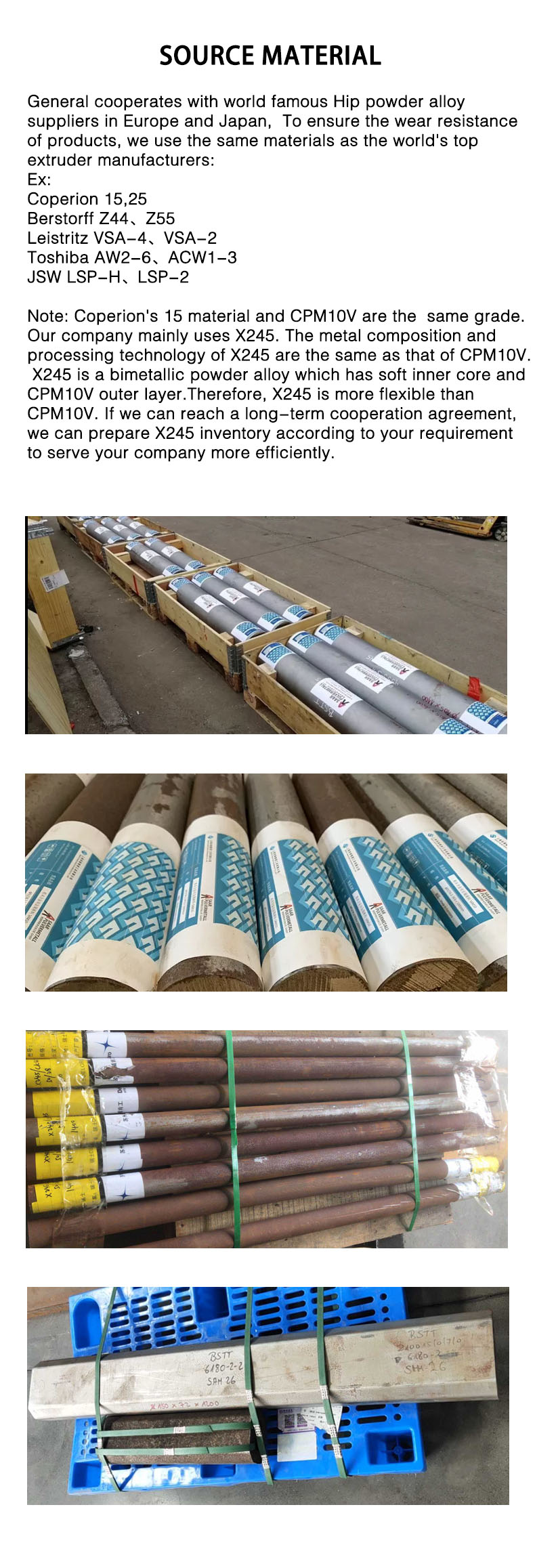

Material: 45 Steel, 38CrMoAlA, Hastelloy C,etc.

Properties:Wear-resisting, Corrode-resisting and Durable

Structural Features

Side-Opening Layout: The barrel features one or more openings on its side (horizontally perpendicular to the axial direction). These openings are typically circular or rectangular and are connected to external devices (such as side feeders, venting valves, or sensors) via flanges, quick-connect interfaces, or sealed covers. The opening positions are precisely aligned with the functional zones of the screw elements (e.g., mixing section, melting section).

Compatibility with Figure-8 Channels: Designed for the figure-8 bore configuration of twin-screw extruders, the side openings are positioned to avoid interference with the screw engagement area, ensuring smooth screw rotation while maintaining continuous flow paths.

Functions

Precise Side Feeding & Staged Addition

Enables the addition of secondary raw materials (e.g., glass fiber, carbon powder, flame retardants) during extrusion, preventing premature degradation of heat-sensitive additives in the high-temperature feed zone or clogging of highly filled materials at the main feed port.

Example: In producing glass fiber-reinforced PP, fibers are added via the side opening in the melting zone to minimize aspect ratio loss.

Targeted Venting & Pressure Regulation

When connected to a vacuum system, side openings can selectively remove volatiles (e.g., moisture, low-molecular-weight compounds), particularly useful when gases are released after melting. Some openings are equipped with pressure valves to relieve excessive local pressure, protecting the barrel and screw.

Enhanced Mixing & Dispersion

Side feeders work in synergy with screw mixing elements (e.g., kneading blocks), ensuring that side-fed materials are immediately subjected to shear forces for rapid dispersion into the main melt stream, improving mixing uniformity (e.g., better color consistency when adding masterbatches).

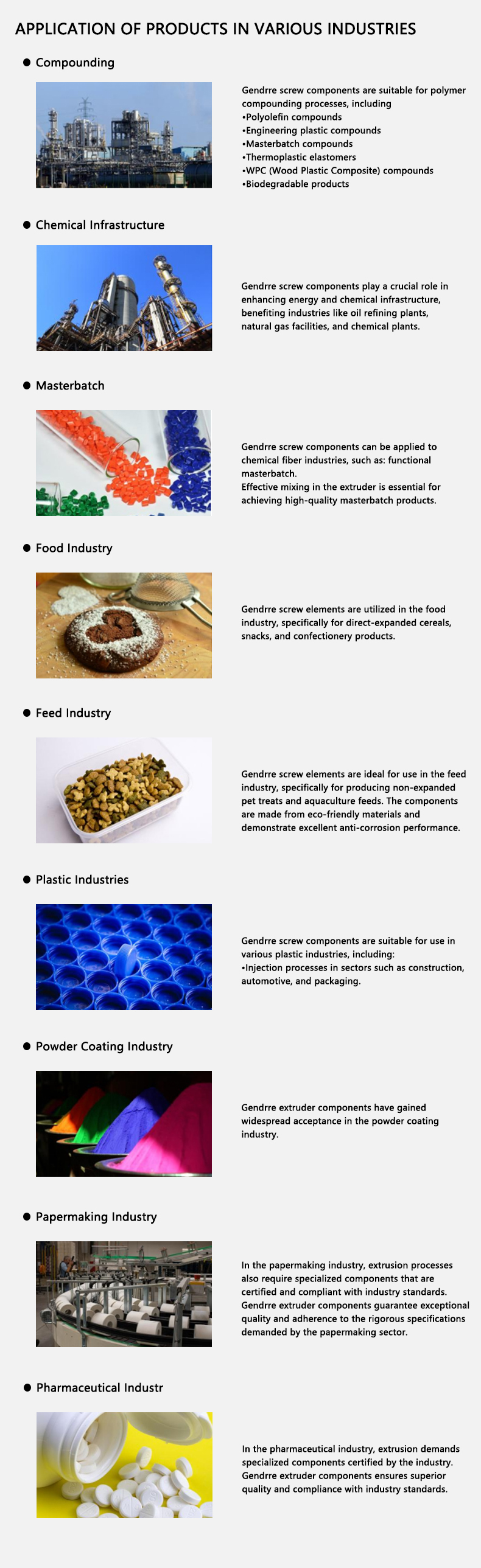

Applications

Highly Filled Composite Processing

Used in producing glass/carbon fiber-reinforced plastics (e.g., PA66 + 30% GF) or mineral-filled PE (e.g., 50% CaCO₃), where fillers are added via side openings to prevent bridging at the main feed port while ensuring uniform dispersion in subsequent mixing zones.

Multi-component Blending

Ideal for polymer blends (e.g., PP/PE alloys) or functional masterbatch production (e.g., antibacterial masterbatch). The primary material is fed and melted at the main feed port, while secondary components are added via side openings for precise ratio control and dispersion.

Reactive Extrusion & Modification

In reactions like PP-g-MAH (maleic anhydride grafting), initiators or monomers are injected into molten PP through side openings to avoid premature reactions in the high-temperature main feed zone, improving grafting efficiency.

Recycled Material Impurity Handling

When processing recycled plastics with minor impurities, side openings can connect to filtration or impurity separation devices, removing contaminants during extrusion to reduce wear on screws and dies.

Differences Between Side-Opening Barrels and Top-Opening Barrels

Different Feeding Methods

Side-opening barrels: Utilize side feeders for forced material conveying, suitable for applications requiring precise feeding control.

Top-opening barrels: Primarily rely on gravity-assisted feeding, better suited for free-flowing materials.

Different Material Compatibility

Side-opening barrels: Specifically designed for high-viscosity, high-fill or heat-sensitive materials such as glass fiber reinforced plastics and reactive modified materials.

Top-opening barrels: More appropriate for free-flowing pellets or powders, commonly used in small-scale laboratory testing.

Different Pressure Resistance Capabilities

Side-opening barrels: Feature stricter sealing designs to withstand higher pressures, ensuring processing stability.

Top-opening barrels: With lower sealing requirements for gravity feeding, they offer moderate pressure resistance.

Different Typical Applications

Side-opening barrels: Mainly used in high-performance composite production (such as carbon fiber reinforced materials) and reactive extrusion processes requiring staged feeding.

Top-opening barrels: Commonly found in laboratory testing or small-batch production with intermittent feeding.

Extruder Side-Feed Barrel

Product Name: Extruder Side-Feed Barrel

Model:φ11 mm ~φ350mm

Applicable Brands:Most well-known extruders on the market

Material: 45 Steel, 38CrMoAlA, Hastelloy C,etc.

Properties:Wear-resisting, Corrode-resisting and Durable

Structural Features

Side-Opening Layout: The barrel features one or more openings on its side (horizontally perpendicular to the axial direction). These openings are typically circular or rectangular and are connected to external devices (such as side feeders, venting valves, or sensors) via flanges, quick-connect interfaces, or sealed covers. The opening positions are precisely aligned with the functional zones of the screw elements (e.g., mixing section, melting section).

Compatibility with Figure-8 Channels: Designed for the figure-8 bore configuration of twin-screw extruders, the side openings are positioned to avoid interference with the screw engagement area, ensuring smooth screw rotation while maintaining continuous flow paths.

Functions

Precise Side Feeding & Staged Addition

Enables the addition of secondary raw materials (e.g., glass fiber, carbon powder, flame retardants) during extrusion, preventing premature degradation of heat-sensitive additives in the high-temperature feed zone or clogging of highly filled materials at the main feed port.

Example: In producing glass fiber-reinforced PP, fibers are added via the side opening in the melting zone to minimize aspect ratio loss.

Targeted Venting & Pressure Regulation

When connected to a vacuum system, side openings can selectively remove volatiles (e.g., moisture, low-molecular-weight compounds), particularly useful when gases are released after melting. Some openings are equipped with pressure valves to relieve excessive local pressure, protecting the barrel and screw.

Enhanced Mixing & Dispersion

Side feeders work in synergy with screw mixing elements (e.g., kneading blocks), ensuring that side-fed materials are immediately subjected to shear forces for rapid dispersion into the main melt stream, improving mixing uniformity (e.g., better color consistency when adding masterbatches).

Applications

Highly Filled Composite Processing

Used in producing glass/carbon fiber-reinforced plastics (e.g., PA66 + 30% GF) or mineral-filled PE (e.g., 50% CaCO₃), where fillers are added via side openings to prevent bridging at the main feed port while ensuring uniform dispersion in subsequent mixing zones.

Multi-component Blending

Ideal for polymer blends (e.g., PP/PE alloys) or functional masterbatch production (e.g., antibacterial masterbatch). The primary material is fed and melted at the main feed port, while secondary components are added via side openings for precise ratio control and dispersion.

Reactive Extrusion & Modification

In reactions like PP-g-MAH (maleic anhydride grafting), initiators or monomers are injected into molten PP through side openings to avoid premature reactions in the high-temperature main feed zone, improving grafting efficiency.

Recycled Material Impurity Handling

When processing recycled plastics with minor impurities, side openings can connect to filtration or impurity separation devices, removing contaminants during extrusion to reduce wear on screws and dies.

Differences Between Side-Opening Barrels and Top-Opening Barrels

Different Feeding Methods

Side-opening barrels: Utilize side feeders for forced material conveying, suitable for applications requiring precise feeding control.

Top-opening barrels: Primarily rely on gravity-assisted feeding, better suited for free-flowing materials.

Different Material Compatibility

Side-opening barrels: Specifically designed for high-viscosity, high-fill or heat-sensitive materials such as glass fiber reinforced plastics and reactive modified materials.

Top-opening barrels: More appropriate for free-flowing pellets or powders, commonly used in small-scale laboratory testing.

Different Pressure Resistance Capabilities

Side-opening barrels: Feature stricter sealing designs to withstand higher pressures, ensuring processing stability.

Top-opening barrels: With lower sealing requirements for gravity feeding, they offer moderate pressure resistance.

Different Typical Applications

Side-opening barrels: Mainly used in high-performance composite production (such as carbon fiber reinforced materials) and reactive extrusion processes requiring staged feeding.

Top-opening barrels: Commonly found in laboratory testing or small-batch production with intermittent feeding.

content is empty!