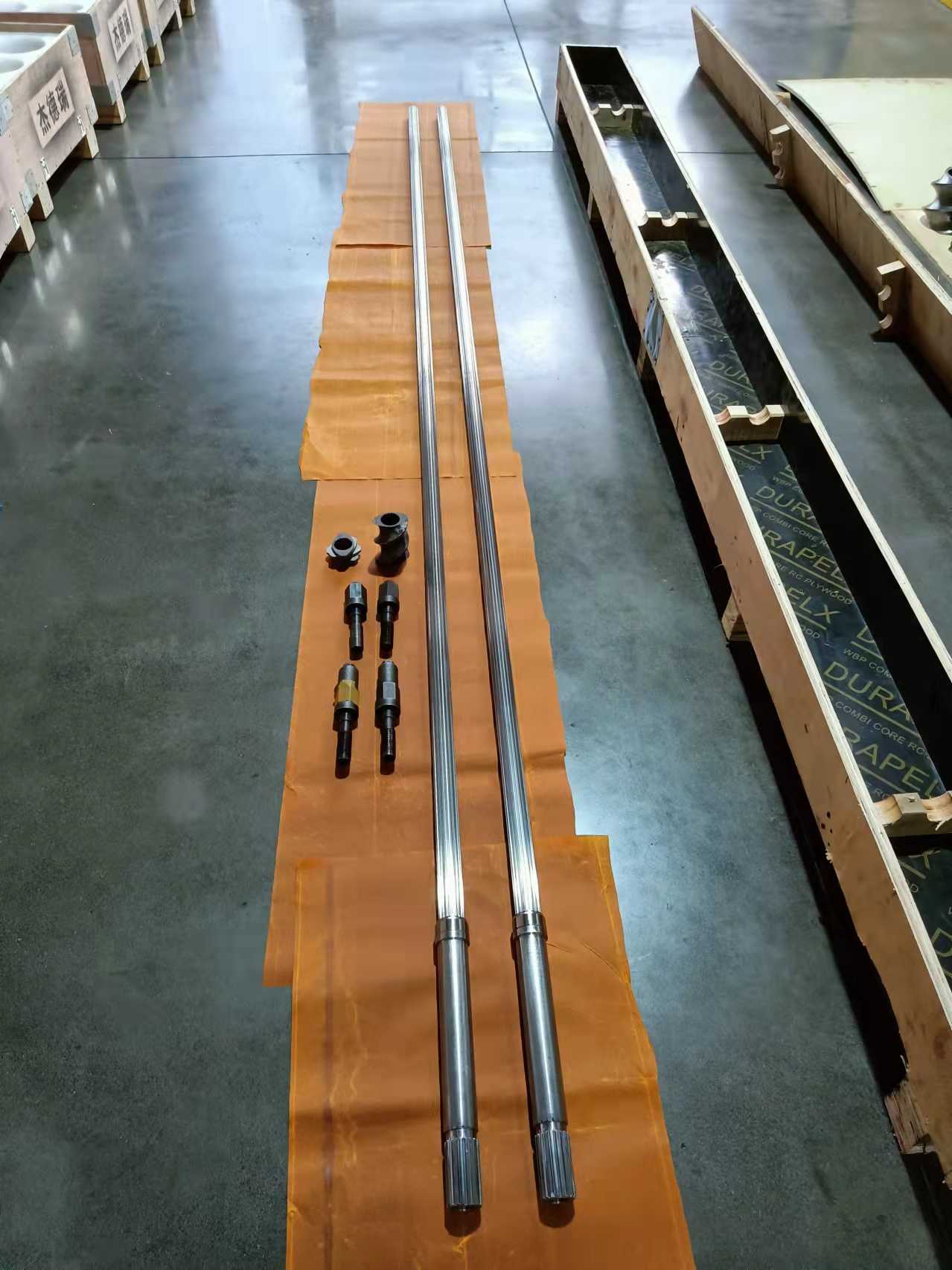

Milling Shaft

Model:φ10 mm ~φ140mm

Length: Up to 15 meters at maximum

Applicable brands:Most well-known extruders on the market

Material : High-Torque Alloy Steel (with a torque rating up to 18Nm/cm²)

Properties : Wear-resisting, Corrode-resisting and durable

Spline Types : DIN5480, JIS-B-1603, GB3478 Involute Splines, Hexagonal Keys, Flat Keyway Semi-Circular Keys, Rectangular Splines

Manufacturing Principle of Traditional Spline Milling Shafts:

The manufacturing of traditional spline milling shafts is based on the principle of metal cutting. Through a series of precision processes, alloy steel billets are transformed into transmission components with specific tooth profiles and precision.

Core Technical Advantages:

Continuity of Metal Fibers: The milling process does not disrupt the internal fiber flow of the material, increasing the fatigue resistance life of spline teeth by over 30% compared to cutting processes.

Processing Flexibility: By replacing milling cutters or adjusting programs, it can quickly switch to processing splines of different specifications, making it suitable for multi-variety and small-batch production.

Cost-Effectiveness: Compared with cold rolling or precision forging, the milling process requires lower equipment investment and shorter debugging cycles, reducing the unit cost by 20%-30%.

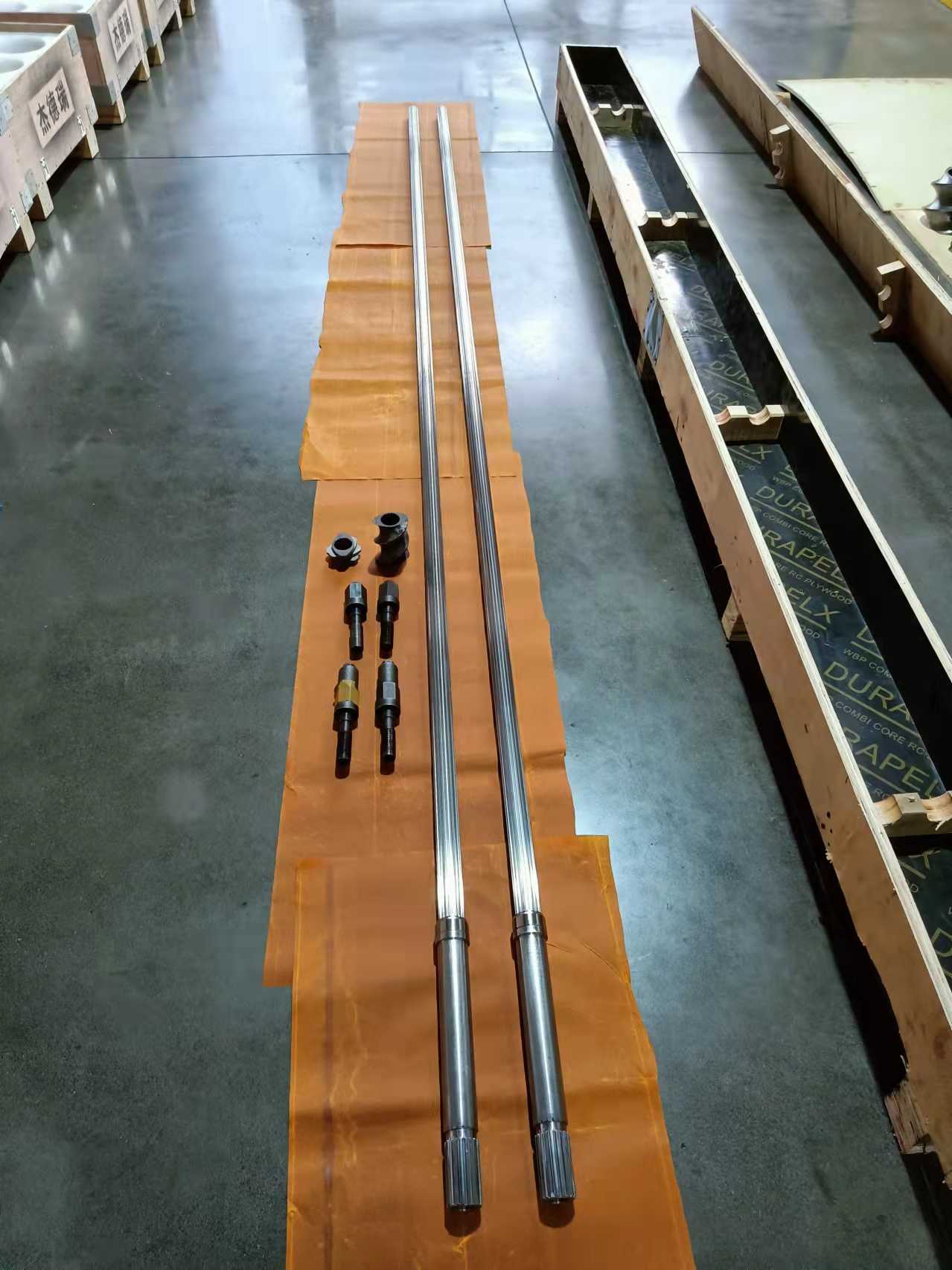

Milling Shaft

Model:φ10 mm ~φ140mm

Length: Up to 15 meters at maximum

Applicable brands:Most well-known extruders on the market

Material : High-Torque Alloy Steel (with a torque rating up to 18Nm/cm²)

Properties : Wear-resisting, Corrode-resisting and durable

Spline Types : DIN5480, JIS-B-1603, GB3478 Involute Splines, Hexagonal Keys, Flat Keyway Semi-Circular Keys, Rectangular Splines

Manufacturing Principle of Traditional Spline Milling Shafts:

The manufacturing of traditional spline milling shafts is based on the principle of metal cutting. Through a series of precision processes, alloy steel billets are transformed into transmission components with specific tooth profiles and precision.

Core Technical Advantages:

Continuity of Metal Fibers: The milling process does not disrupt the internal fiber flow of the material, increasing the fatigue resistance life of spline teeth by over 30% compared to cutting processes.

Processing Flexibility: By replacing milling cutters or adjusting programs, it can quickly switch to processing splines of different specifications, making it suitable for multi-variety and small-batch production.

Cost-Effectiveness: Compared with cold rolling or precision forging, the milling process requires lower equipment investment and shorter debugging cycles, reducing the unit cost by 20%-30%.