Views: 0 Author: Site Editor Publish Time: 2026-01-18 Origin: Site

Extruder barrels are one of the most crucial components in extrusion processes. Whether in plastic, rubber, food, or chemical industries, their performance directly impacts production efficiency and product quality. Regular cleaning of extruder barrels is not only a matter of maintaining the equipment but also a necessary step in ensuring that production continues without interruptions. In this guide, we will explore the importance of cleaning extruder barrels, provide a step-by-step process for effective cleaning, and share tips on maintenance and frequency of cleaning.

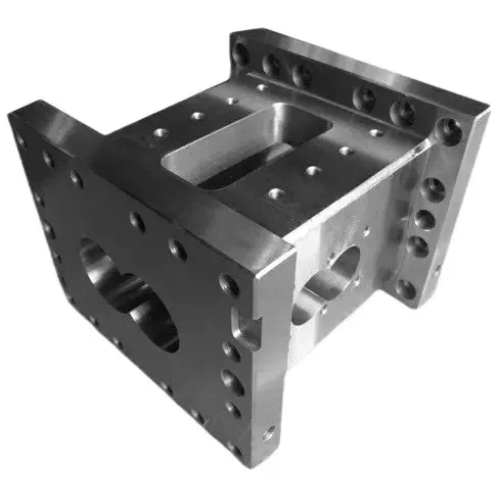

Extruder barrels are used in many manufacturing processes where material is melted, mixed, and forced through a die to shape or form a product.

The extruder barrel provides the chamber in which raw materials such as plastic pellets or rubber are heated to a molten state, then pushed through the machine's die by the extruder screw. The extrusion process is widely used in manufacturing items like pipes, sheets, films, and food products, as well as in the rubber and plastic industries.

The barrel is typically made of a strong steel alloy that can withstand high temperatures and pressure. Inside the barrel, there are grooves or channels that interact with the screw, helping to drive material forward. This process requires precision, as the extrusion’s success depends on uniform pressure and temperature distribution. As such, a clean barrel is critical for maintaining consistent product quality and efficiency in operations.

Keeping your extruder barrel clean is essential for several reasons:

Preventing Material Build-up: Over time, various materials can accumulate inside the barrel, especially if you're processing different resins, additives, or colorants. This build-up can obstruct the screw’s movements, leading to uneven melting and extrusion. Furthermore, residue can contaminate subsequent materials, affecting the quality of your products.

Maintaining High Product Quality: If contamination from previous runs mixes with fresh material, it can lead to discoloration, poor mixing, and defects in the final product. Cleaning helps ensure that each batch of material is processed in a pristine environment.

Improving Operational Efficiency: A clean extruder barrel can function at its peak performance. Build-ups or contaminants within the barrel can cause the machine to work harder, increasing wear and tear on the equipment, leading to more frequent breakdowns and downtime.

Extending Equipment Life: Regular cleaning not only improves the efficiency of the extruder but also helps prolong the life of the barrel, preventing damage caused by residue and buildup over time.

Cleaning the extruder barrel requires some specialized tools and equipment to ensure the process is efficient, safe, and effective. Below is a list of the key tools and materials you'll need:

Tool/Equipment | Purpose | Recommended |

Cleaning Scrapers | To remove large chunks of residue from inside the barrel | Stainless steel scrapers |

Cleaning Brushes | For smaller residue and areas that scrapers can't reach | Nylon or brass brushes |

Pressure Washer | To clean the exterior and reach hard-to-access spots | High-pressure nozzle |

Solvent-based Cleaning Solution | To dissolve sticky residues or build-ups inside the barrel | Industrial-grade cleaning agent |

Automated Cleaning System | For facilities with larger production runs, saves time and ensures thorough cleaning | Automated cleaning equipment |

Each of these tools plays a critical role in achieving a thorough clean. Depending on the level of contamination, some processes may involve more specialized cleaning agents or more intensive methods.

Below is a detailed, step-by-step guide for cleaning an extruder barrel. While the process can vary depending on the level of contamination and type of material used, this guide covers the general procedure.

Before starting the cleaning process, ensure that the extruder is powered down and cool. This step is important for safety reasons and to avoid damaging the barrel. Here’s what you need to do:

Power off the extruder and allow it to cool down completely to a safe handling temperature.

Inspect the equipment to ensure no loose parts or components could interfere with the cleaning process.

Wear protective gloves and safety goggles to prevent contact with hot surfaces or cleaning agents.

If your extruder barrel has parts that can be removed for cleaning (such as screws or nozzles), disassemble them carefully. Some extruder barrels are modular, which means they have removable sections that make the cleaning process easier.

Remove screws or nozzles if needed, taking note of their positions for reassembly.

Clean the removed parts individually before reinserting them into the barrel.

After disassembly, the next step is to begin cleaning the interior. Start with the exterior if necessary, especially if the barrel has visible contamination on the outside. For internal cleaning, use the following steps:

Scrape the barrel’s interior using a cleaning scraper or wire brush to remove any loose residue or large chunks.

Be careful not to damage the barrel’s surface, as scratches can make it more difficult to clean in the future.

If residue remains after the initial cleaning, a more thorough cleaning is necessary. This step typically involves using specialized cleaning solutions.

Apply a solvent-based cleaning solution to the interior of the extruder barrel. The solution will break down hardened residues and materials that the scraper and brush could not remove.

Allow the solvent to sit for a specified period (usually 15 to 30 minutes), depending on the level of contamination.

Use pressure washers or automated cleaning systems for more intensive cleaning if necessary.

After the deep cleaning process, thoroughly rinse the extruder barrel to remove all cleaning agents, solvents, and residue. This is essential to prevent contamination of future batches.

Use warm water and a pressure washer to rinse the inside and outside of the barrel. Ensure all cleaning solution is flushed out of the barrel.

Dry the barrel completely to prevent rust. Some prefer using dry air blowers or allowing the barrel to air-dry in a controlled environment.

Once the barrel has dried, reassemble any parts that were removed during the cleaning process. Double-check that everything is securely in place.

Check the barrel for any missed residue or areas that may need additional cleaning.

Test the barrel in a small batch production run to ensure it operates smoothly and efficiently.

After cleaning, it’s essential to implement a maintenance routine to keep the extruder barrel in optimal condition:

Regular Inspection: Schedule monthly inspections to check for any signs of wear and tear. Look for scratches, corrosion, or build-up.

Proper Lubrication: Keep the moving parts of the extruder lubricated to prevent friction and wear.

Avoid Overheating: Ensure that the temperature and pressure in the barrel stay within the manufacturer’s recommended range.

Preventative Cleaning: Clean the barrel regularly to avoid heavy residue build-up that could become harder to remove over time.

Cleaning extruder barrels can be challenging, especially when dealing with stubborn residues or hard-to-reach areas. Here are some common issues and solutions:

Stubborn Material Build-up: Materials like carbonized plastic or rubber can be difficult to clean. Use specialized cleaning agents designed for these materials.

Excessive Corrosion: If corrosion is found, it may be necessary to replace certain parts of the barrel. Prevent corrosion by ensuring the barrel is always dried completely after cleaning.

Hard-to-Reach Areas: Use small brushes or automated systems to clean narrow spaces and grooves.

The frequency of cleaning depends on the material being processed, production volume, and the specific requirements of the extruder. Here are some general guidelines:

After each major production run: Clean the barrel thoroughly when switching between different types of materials or colors.

Every 100 to 200 hours of operation: For standard production, plan for a more thorough cleaning at least every few weeks or after a certain number of operation hours.

Scheduled Preventive Maintenance: Perform light cleaning or inspection during scheduled maintenance to avoid major build-ups.

Regular cleaning of extruder barrels is essential for maintaining optimal production efficiency and ensuring the consistent quality of your products. By following a detailed cleaning routine, incorporating proactive maintenance practices, and adhering to scheduled cleaning intervals, you can significantly extend the lifespan of your extruder equipment and boost overall productivity.

At Gendrre, we understand the importance of well-maintained extrusion systems and offer high-quality, precision-engineered extruder barrels that are designed for durability and performance. Our team is dedicated to providing expert guidance on cleaning and maintenance, ensuring that your machinery operates at its peak.

For more information on how to keep your extruder barrel in top condition or to explore our range of products, feel free to get in touch with us. We are here to support your production needs and help you optimize your equipment’s performance.

Why is it important to clean an extruder barrel regularly?

Regular cleaning ensures that residues do not build up, which can cause contamination, affect product quality, and decrease machine efficiency.

How can I tell when my extruder barrel needs cleaning?

Signs that cleaning is needed include inconsistent product quality, visible residue or material buildup, or unusual noises from the barrel during operation.

Can I use household cleaning agents for my extruder barrel?

It is best to use specialized cleaning solutions designed for industrial machinery to ensure safety and effectiveness.

How often should I clean my extruder barrel?

Cleaning frequency depends on the type of material processed, but generally, after each major run or every 100 to 200 hours of operation is recommended.

Are automated cleaning systems effective for cleaning extruder barrels?

Yes, automated systems can save time and ensure a thorough clean, especially for large-scale operations with high production volume.