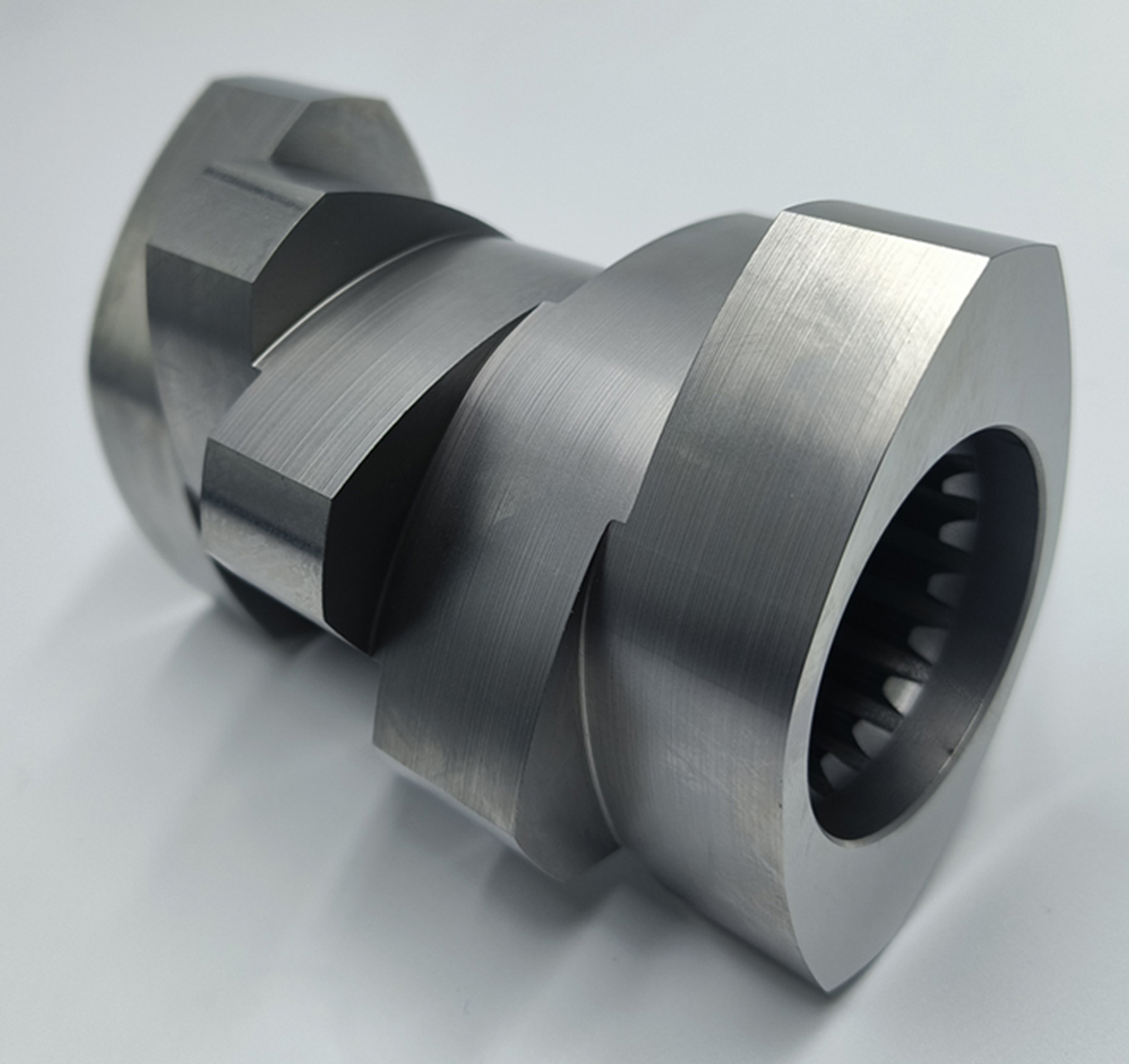

Backward Pumping Kneading Block

Product Name : Backward Pumping Kneading Block

Model:φ15 mm ~φ350mm

Applicable Brands:Most well-known extruders on the market

Material : Tool steel, HIP, stainless steel, nickel-based alloy, cobalt-based alloy, etc.

Properties :Wear-resisting, Corrode-resisting and Durable

Structure Characteristics:

The backward pumping kneading block consists of staggered kneading disks, with the helix angle formed by the staggered arrangement consistent with the spiral direction of the reverse screw element. Its design integrates staggered disks and reverse threads to achieve backward material conveying.

Functions:

By impeding the forward conveying of materials through reverse action, its core function is to extend the material residence time in the barrel, thereby increasing filling degree and material pressure, and significantly enhancing mixing efficiency. The backpressure generated converts total flow into leakage flow, improving material filling in the upstream screw conveying elements.

In the melting process, the backward pumping kneading block affects polymer melting efficiency and energy consumption: higher resistance prolongs material residence time, facilitating full melting of polymers; however, excessive resistance may cause melt overheating, which is detrimental to mixing and molding. Therefore, its design must be adjusted according to specific parameters such as screw speed and feed rate to precisely control material filling degree and residence time, optimizing energy efficiency in polymer melting.

Applications:

Widely used in plastic processing, including:

High-fill modification processes, ensuring uniform dispersion of fillers in plastics to enhance product performance;

Masterbatch production, guaranteeing consistent distribution of pigments/dyes to avoid color differences;

Reactive extrusion, providing necessary shearing and mixing to promote thorough chemical reactions.

With strong shearing, high mixing efficiency, and backpressure control capabilities, it is the preferred component for processing high-viscosity materials requiring intense shear, and is widely applied in various high-end plastic processing scenarios.

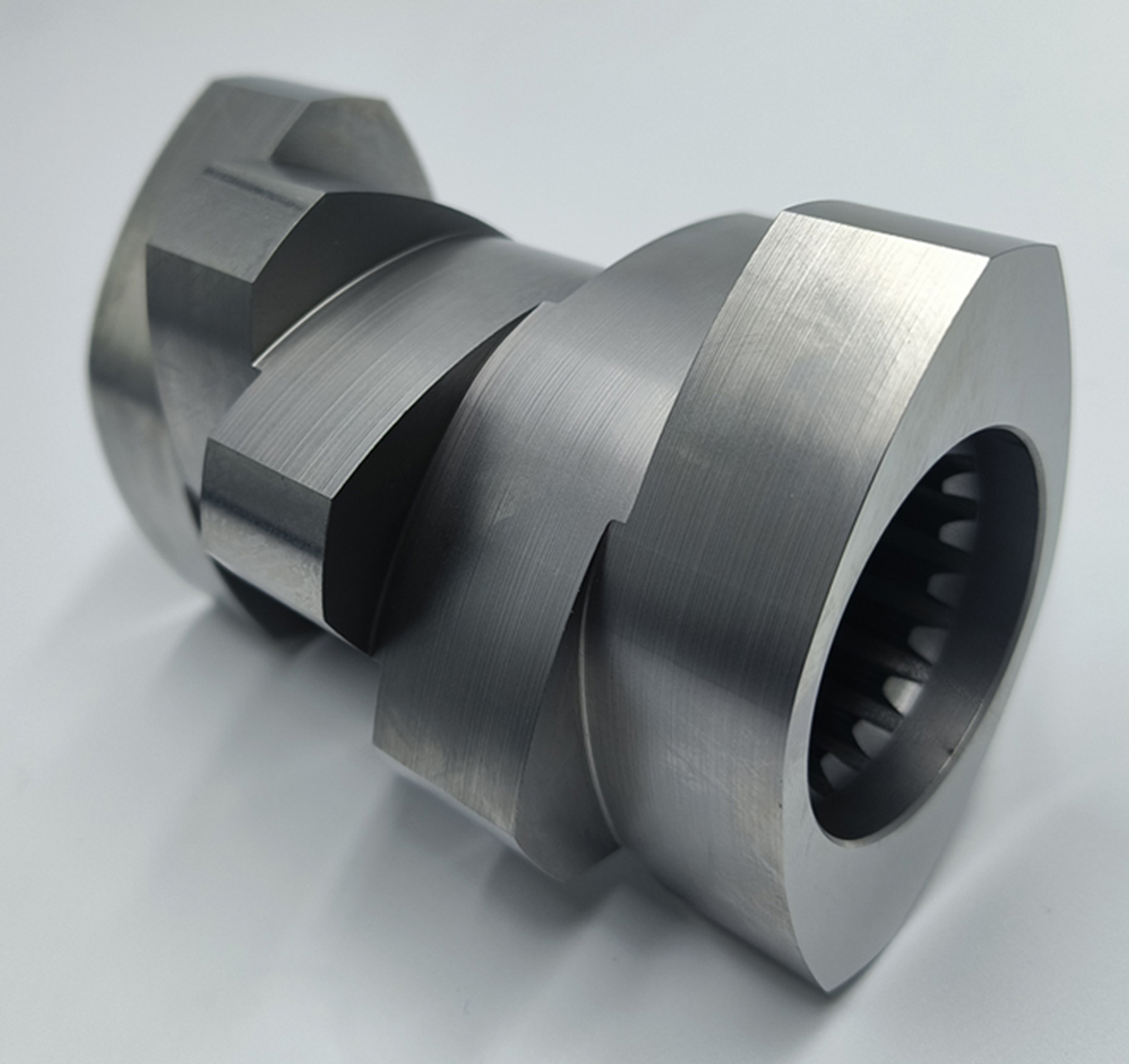

Backward Pumping Kneading Block

Product Name : Backward Pumping Kneading Block

Model:φ15 mm ~φ350mm

Applicable Brands:Most well-known extruders on the market

Material : Tool steel, HIP, stainless steel, nickel-based alloy, cobalt-based alloy, etc.

Properties :Wear-resisting, Corrode-resisting and Durable

Structure Characteristics:

The backward pumping kneading block consists of staggered kneading disks, with the helix angle formed by the staggered arrangement consistent with the spiral direction of the reverse screw element. Its design integrates staggered disks and reverse threads to achieve backward material conveying.

Functions:

By impeding the forward conveying of materials through reverse action, its core function is to extend the material residence time in the barrel, thereby increasing filling degree and material pressure, and significantly enhancing mixing efficiency. The backpressure generated converts total flow into leakage flow, improving material filling in the upstream screw conveying elements.

In the melting process, the backward pumping kneading block affects polymer melting efficiency and energy consumption: higher resistance prolongs material residence time, facilitating full melting of polymers; however, excessive resistance may cause melt overheating, which is detrimental to mixing and molding. Therefore, its design must be adjusted according to specific parameters such as screw speed and feed rate to precisely control material filling degree and residence time, optimizing energy efficiency in polymer melting.

Applications:

Widely used in plastic processing, including:

High-fill modification processes, ensuring uniform dispersion of fillers in plastics to enhance product performance;

Masterbatch production, guaranteeing consistent distribution of pigments/dyes to avoid color differences;

Reactive extrusion, providing necessary shearing and mixing to promote thorough chemical reactions.

With strong shearing, high mixing efficiency, and backpressure control capabilities, it is the preferred component for processing high-viscosity materials requiring intense shear, and is widely applied in various high-end plastic processing scenarios.